Hazardous Location Air Curtains

Overview

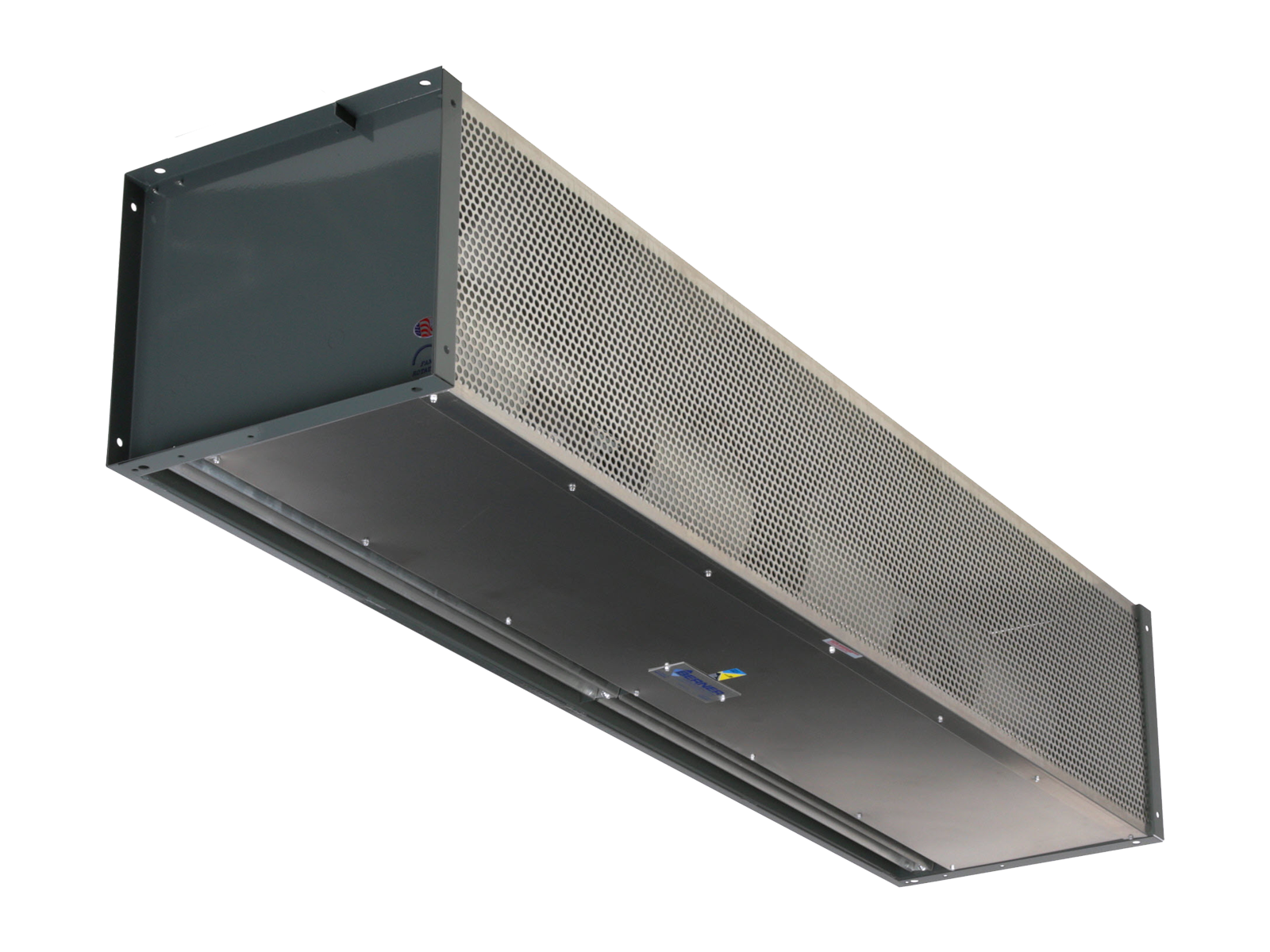

The Berner Hazardous Location Series 12 Air Curtain is specifically designed for environments where gases may pose a hazardous situation. Compliant with ANSI/NFPA-70 National Electrical Code (NEC) for Electrical Equipment in Class I, Division 1 and 2, Groups C and D for gases, this air curtain ensures safety, stable temperatures, and insect control when doors are open. Engineered for performance and durability, it is a reliable choice for hazardous locations.

Features

Mounting Heights: Suitable for mounting heights up to 12 feet for environmental separation and 10 feet for insect control.

Compliance: Designed and manufactured to comply with Class I, Division 1 and 2, Groups C and D for gases.

Construction: Features a gray zinc epoxy powder-coated aluminized steel cabinet with aluminum screen and access panels.

Durability: Engineered to perform and built to last, ensuring long-term reliability in hazardous environments.

Ease of Use: Simple to install, operate, and maintain.

Size Options: Available in single lengths from 3 feet to 16 feet.

Construction: Compliant with Class I, Division 1 & 2, Groups C & D.

Motor: ½ hp explosion-proof single-speed motor(s) with temperature code T3C.

Exterior: Gray zinc epoxy powder-coated aluminized steel cabinet.

Impellers: Aluminum impellers in a matching housing.

Mounting: Wall and top mounting.

Nozzle: High efficiency Pro-V Nozzle.

Junction Box: External Mount Explosion Proof Junction Box (one per motor).

Construction: Compliant with Class I, Division 1 & 2, Groups C & D.

Motor: ½ hp explosion-proof single-speed motor(s) with temperature code T3C.

Exterior: Gray zinc epoxy powder-coated aluminized steel cabinet.

Impellers: Aluminum impellers in a matching housing.

Mounting: Wall and top mounting.

Nozzle: High efficiency Pro-V Nozzle.

Applications

The Berner Hazardous Location Series 12 Air Curtain is ideal for:

- Hazardous Locations:

- Function: Provides an effective air barrier in areas where gases may create hazardous situations, maintaining stable temperatures and preventing flying insects from entering.

- Benefits: Ensures compliance with safety standards, protects employees, and maintains environmental control in hazardous settings.

Overview

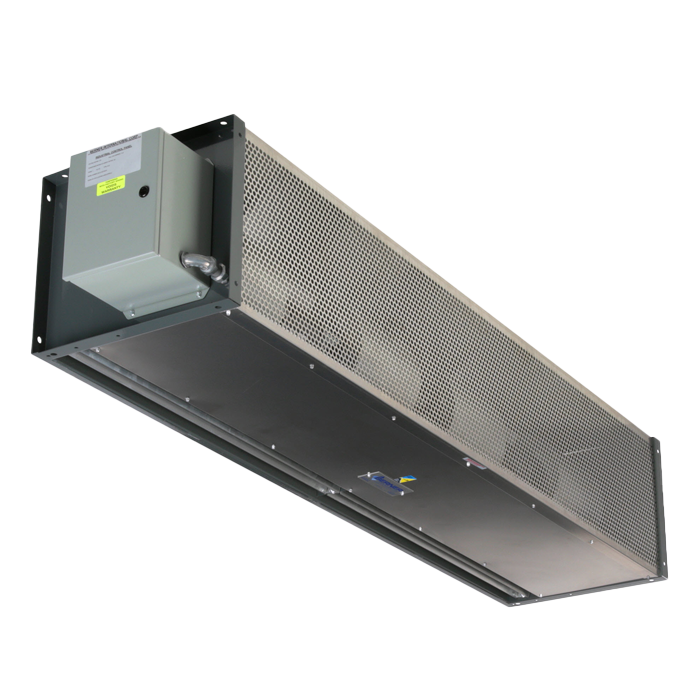

The Berner Industrial Washdown 14 Air Curtain is specifically engineered for environments that require frequent washdowns, such as food processing facilities. This durable air curtain features all-welded stainless steel construction with a gray powder-coated exterior. It is designed to save energy, maintain stable temperatures, and keep flying insects out when doors are open. With a focus on durability and performance, it is an ideal solution for washdown applications.

Mounting Heights: Suitable for mounting heights up to 14 feet for environmental separation and 12 feet for insect control.

Construction: All-welded stainless steel with a gray powder-coated exterior.

Durability: Engineered for washdown applications, ensuring long-term reliability even under frequent cleaning conditions.

Ease of Use: Simple to install, operate, and maintain.

Certification: Berner is a UL Listed panel shop, authorized to build UL listed Motor Control Panels.

Size Options: Available in single lengths from 3 feet to 16 feet.

Type: Single-speed motor with 300 series stainless hardware.

Sealant: Moisture sealant on bolt heads, frame, and endplate.

Gaskets: Neoprene gaskets for enhanced protection.

Bearings: Double-sealed ball bearings with built-in drain plug.

Seals: Lip and v-ring seal on drive end, slinger on ODE of TEFC motors.

Shaft: Stainless steel shaft with F insulation, tropicalized.

Applications

The Berner Industrial Washdown 14 Air Curtain is designed for use in:

-

Food Processing Facilities:

- Function: Maintains hygiene standards by providing a robust barrier against contaminants while withstanding frequent washdowns.

- Benefits: Ensures compliance with food safety regulations, improves operational efficiency, and protects the working environment.

-

Industrial Washdown Environments:

- Function: Provides a durable solution for environments where equipment is regularly cleaned with high-pressure water.

- Benefits: Enhances the longevity of the air curtain, ensuring reliable performance in challenging conditions.

Overview

The Berner Industrial Corro-Duty 16 Air Curtain is engineered to excel in environments that demand robust protection against severe corrosion and harsh operational conditions. Designed with all-welded stainless steel construction and a gray powder-coated exterior, this air curtain is ideal for applications where maintaining stable temperatures and preventing the intrusion of flying insects is critical. With a focus on durability and performance, it’s built to withstand the toughest environments.

Mounting Heights: Suitable for mounting heights up to 16 feet for environmental separation and 14 feet for insect control.

Construction: All-welded stainless steel with a gray powder-coated exterior.

Durability: Specifically built for Corro-Duty applications, ensuring long-term reliability even in harsh conditions.

Ease of Use: Simple to install, operate, and maintain.

Certification: Berner is a UL Listed panel shop, authorized to build UL listed Motor Control Panels.

Size Options: Available in single lengths from 5 feet to 16 feet.

Type: Single-speed motor with a corrosion-resistant epoxy finish.

Bearings: Sealed pre-lubricated bearings.

Conduit Box: Oversized rotatable cast iron conduit box.

Frames: Cast iron frames with Neoprene V-ring sling.

Construction: Heavy-duty cast iron construction with enhanced ingress protection.

Windings: Moisture-resistant copper windings.

Insulation: Class F insulation, tropicalized.

Nameplate: Stainless steel nameplate with corrosion-resistant hardware.

Applications

The Berner Industrial Corro-Duty 16 Air Curtain is designed for:

-

Petro-Chemical Plants:

- Function: Maintains a barrier against corrosive chemicals and severe environmental conditions.

- Benefits: Enhances operational efficiency and equipment protection.

-

Mines:

- Function: Provides robust protection against harsh conditions.

- Benefits: Ensures a controlled and safe working environment.

-

Foundries:

- Function: Blocks dust and particles while maintaining temperature stability.

- Benefits: Improves worker comfort and equipment longevity.

-

Pulp and Paper Plants:

- Function: Protects against corrosive effects of the production environment.

- Benefits: Ensures efficiency and facility protection.

-

Waste Management Facilities:

- Function: Protects against harsh operational conditions.

- Benefits: Maintains a clean and efficient working environment.

-

Chemical Plants:

- Function: Guards against corrosive processing environments.

- Benefits: Ensures safety and operational effectiveness.

-

Tropical Climates:

- Function: Offers protection against high humidity and corrosive conditions.

- Benefits: Maintains environmental stability and equipment integrity.

Overview

The Berner Industrial Washdown 20 Air Curtain is engineered to deliver superior performance in environments requiring frequent washdowns and exposure to harsh conditions. Featuring all-welded construction with a gray powder-coated stainless steel exterior, this air curtain is designed to maintain energy efficiency, stabilize temperatures, and keep flying insects out when doors are open. It’s built for durability and ease of maintenance, making it an ideal solution for demanding industrial applications.

Mounting Heights: Suitable for mounting heights up to 16 feet for environmental separation and 14 feet for insect control.

Construction: All-welded stainless steel with a gray powder-coated finish.

Durability: Specifically built for washdown applications, ensuring long-term reliability in harsh conditions.

Ease of Use: Simple to install, operate, and maintain.

Certification: Berner is a UL Listed panel shop, authorized to build UL listed Motor Control Panels.

Size Options: Available in single lengths from 5 feet to 16 feet.

Type: Single-speed motor with a corrosion-resistant epoxy finish.

Bearings: Sealed pre-lubricated bearings for extended performance.

Conduit Box: Oversized rotatable cast iron conduit box.

Frames: Heavy-duty cast iron construction with Neoprene V-ring sling.

Ingress Protection: Enhanced ingress protection for reliable operation in challenging conditions.

Windings: Moisture-resistant copper windings.

Insulation: Class F insulation, tropicalized for durability in extreme conditions.

Nameplate: Stainless steel nameplate with corrosion-resistant hardware.

Applications

The Berner Industrial Washdown 20 Air Curtain is designed for:

-

Petro-Chemical Plants:

- Function: Maintains a barrier against corrosive chemicals and severe environmental conditions.

- Benefits: Enhances operational efficiency and equipment protection.

-

Mines:

- Function: Provides durable protection in challenging conditions.

- Benefits: Ensures safety and comfort for workers, and safeguards equipment.

-

Foundries:

- Function: Blocks dust and particles while maintaining temperature control.

- Benefits: Improves working conditions and extends equipment life.

-

Pulp and Paper Plants:

- Function: Protects against the corrosive effects of production environments.

- Benefits: Enhances efficiency and protects facility assets.

-

Waste Management Facilities:

- Function: Maintains protection in harsh waste management conditions.

- Benefits: Ensures a clean and efficient operation.

-

Chemical Plants:

- Function: Guards against corrosive processing conditions.

- Benefits: Ensures safety and effective operations.

-

Tropical Climates:

- Function: Offers reliable performance in high humidity and corrosive conditions.

- Benefits: Maintains environmental stability and equipment integrity.

More Solutions For You

Check out similar products that could be the perfect fit for your unique needs.

Contact Us Today

Have a project in mind? Need a few more details? Fill out the form and we will get back to you as soon as we can.