Berner Products

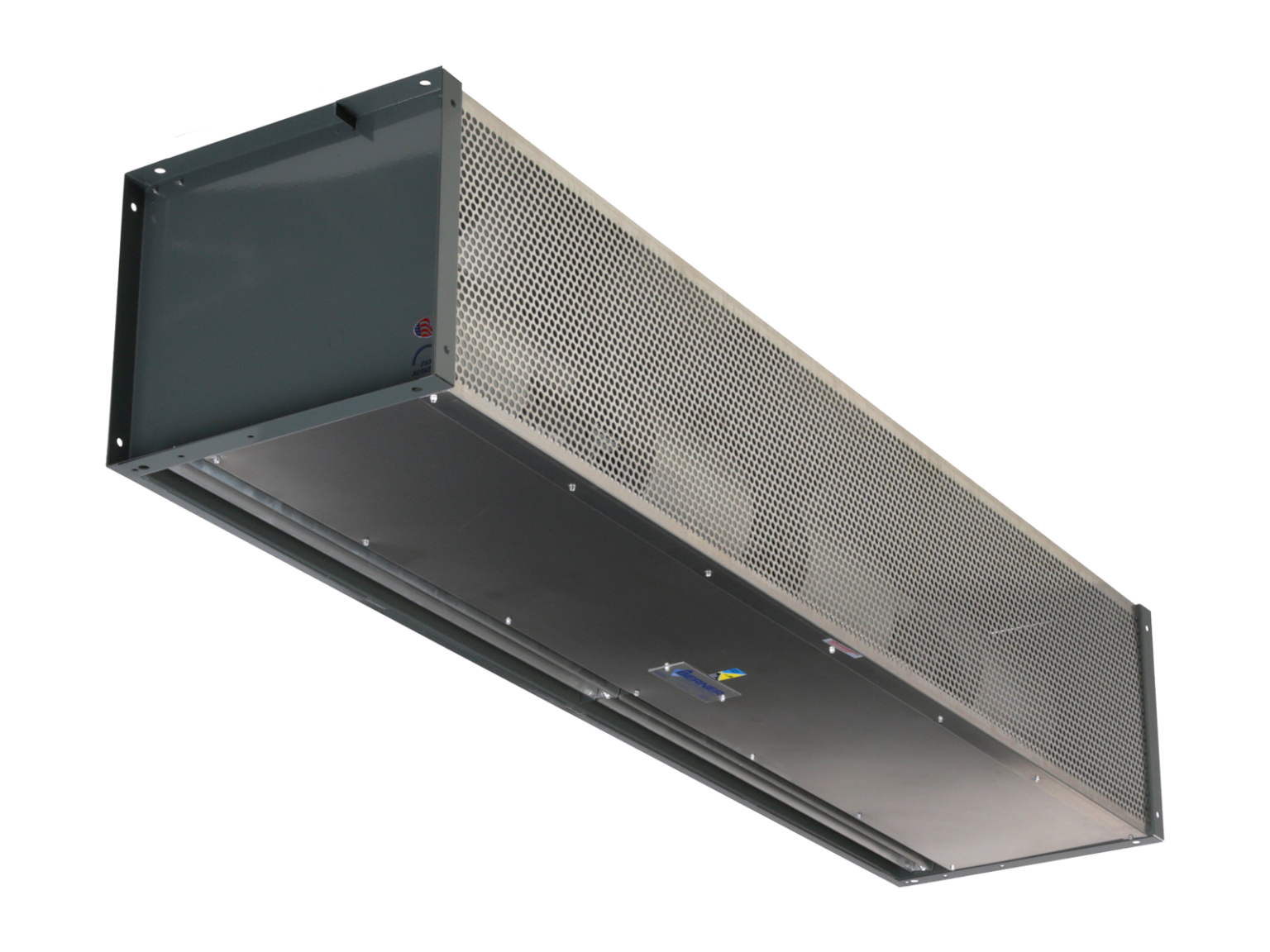

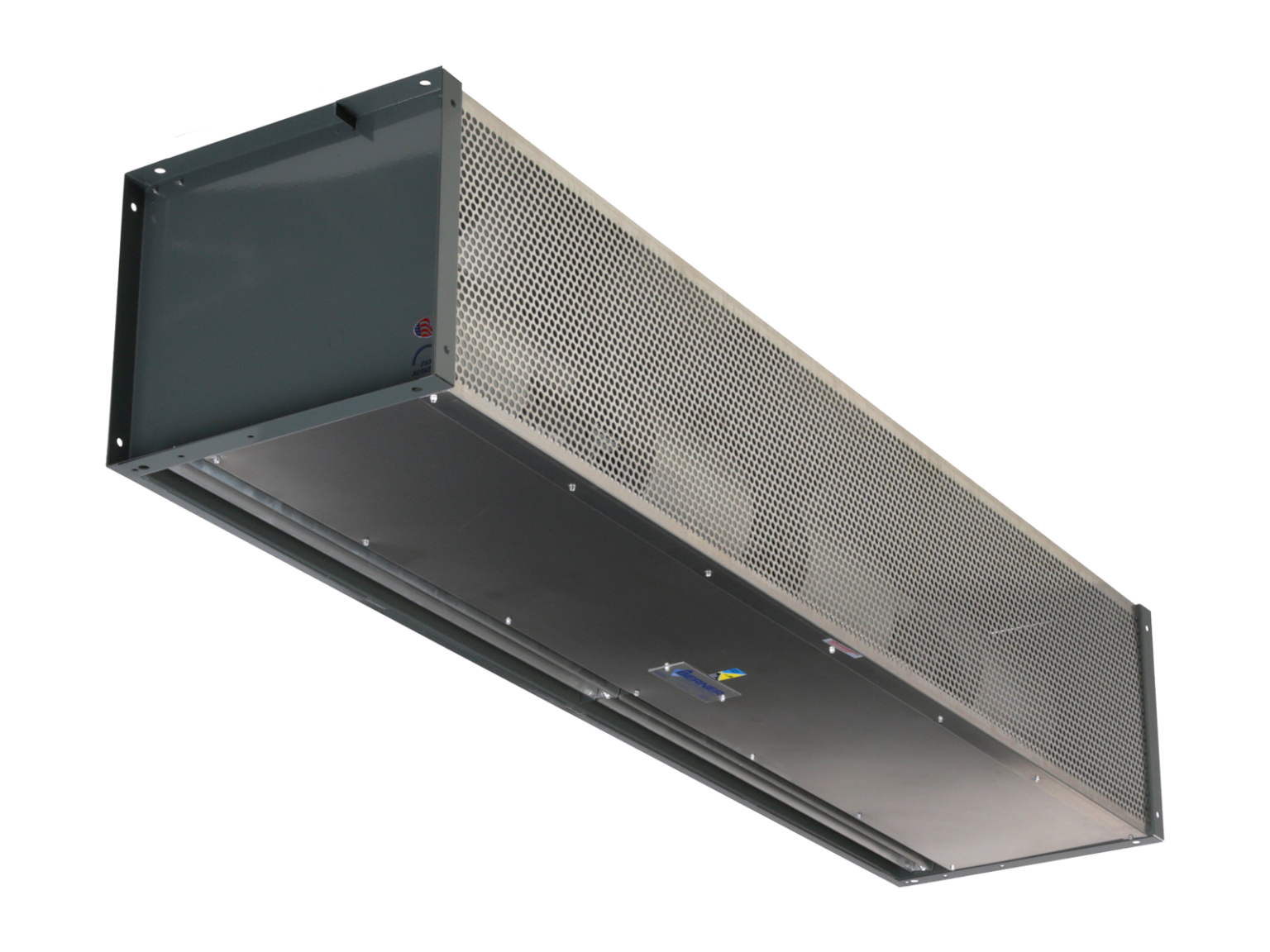

Air Curtains & Air Doors for Hazardous Environments

FEATURES

For mounting heights to 12′ (environmental separation) and 10′ (insect control).

The Berner Hazardous Location Series 12 Air Curtain is designed and manufactured to comply with ANSI/NFPA-70 National Electrical Code (NEC) for Electrical Equipment: Class I, Division 1 and 2, Groups C and D for gases.

- Used in areas where gases may create a hazardous situation to keep temperatures stable and flying insects out when the doors are open.

- Engineered to perform and built to last

- Simple to install, operate, and maintain

- Made in U.S.A.

Available in single lengths from 3′ to 16′

AMBIENT

- Constructed for Class I, Division 1 & 2, Groups C & D

- ½ hp explosion-proof single-speed motor(s) temperature code T3C

- Interior and exterior gray zinc epoxy powder-coated aluminized steel cabinet with aluminum screen and access panels

- External Mount Explosion Proof Junction Box (one per motor)

- Aluminum impellers in a matching housing

- Wall and top mounting

- High efficiency Pro-V Nozzle

STEAM/HOT WATER HEAT

- Constructed for Class I, Division 1 & 2, Groups C & D

- ½ hp explosion-proof single-speed motor(s) temperature code T3C

- Interior and exterior gray zinc epoxy powder-coated aluminized steel cabinet with aluminum screen and access panels

- External Mount Explosion Proof Junction Box (one per motor)

- Aluminum impellers in a matching housing

- Wall and top mounting

- High efficiency Pro-V Nozzle

Coil features:

- Aluminum casing

- 5/8″ copper tube X .035″ wall

- Aluminum fins

- Leak tested at 450 psi

×

Request information about Air Curtains & Air Doors for Hazardous Environments

Call here for more information about Unit#: Air Curtains & Air Doors for Hazardous Environments

Or fill out the form below