Cantilever Racking

Structural Cantilever Racking

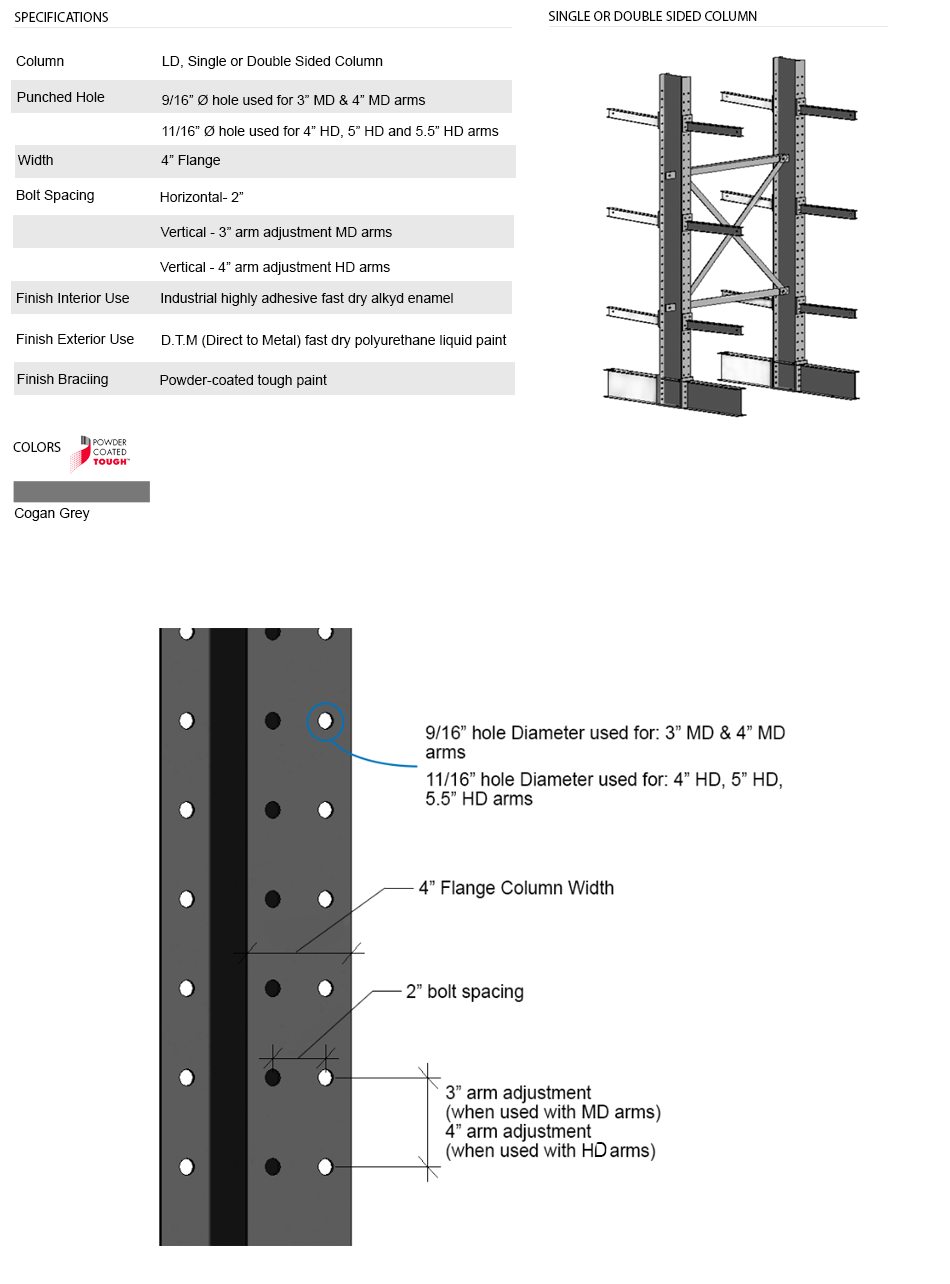

Cogan structural cantilever racking is what you need for handling medium- to extra heavy-duty loads. Ideal for storing short, long or awkwardly-shaped items, our cantilever racking features a special arm system designed for easy front loading without obstruction. Structural steel components guarantee superior strength. Punched holes run the full height of each column upright, providing excellent adaptability and versatility for all of your storage requirements. Built for the toughest industrial applications, all connections use high-strength structural grade bolts.

Our durable, powder-coated paint finish is the Cogan standard and offers ultra-resilient protection for all indoor applications. If outdoor use is required, columns and bases are coated in a polyurethane liquid paint for enhanced durability. Your cantilever racking will look great, even after years of exposure to the elements.

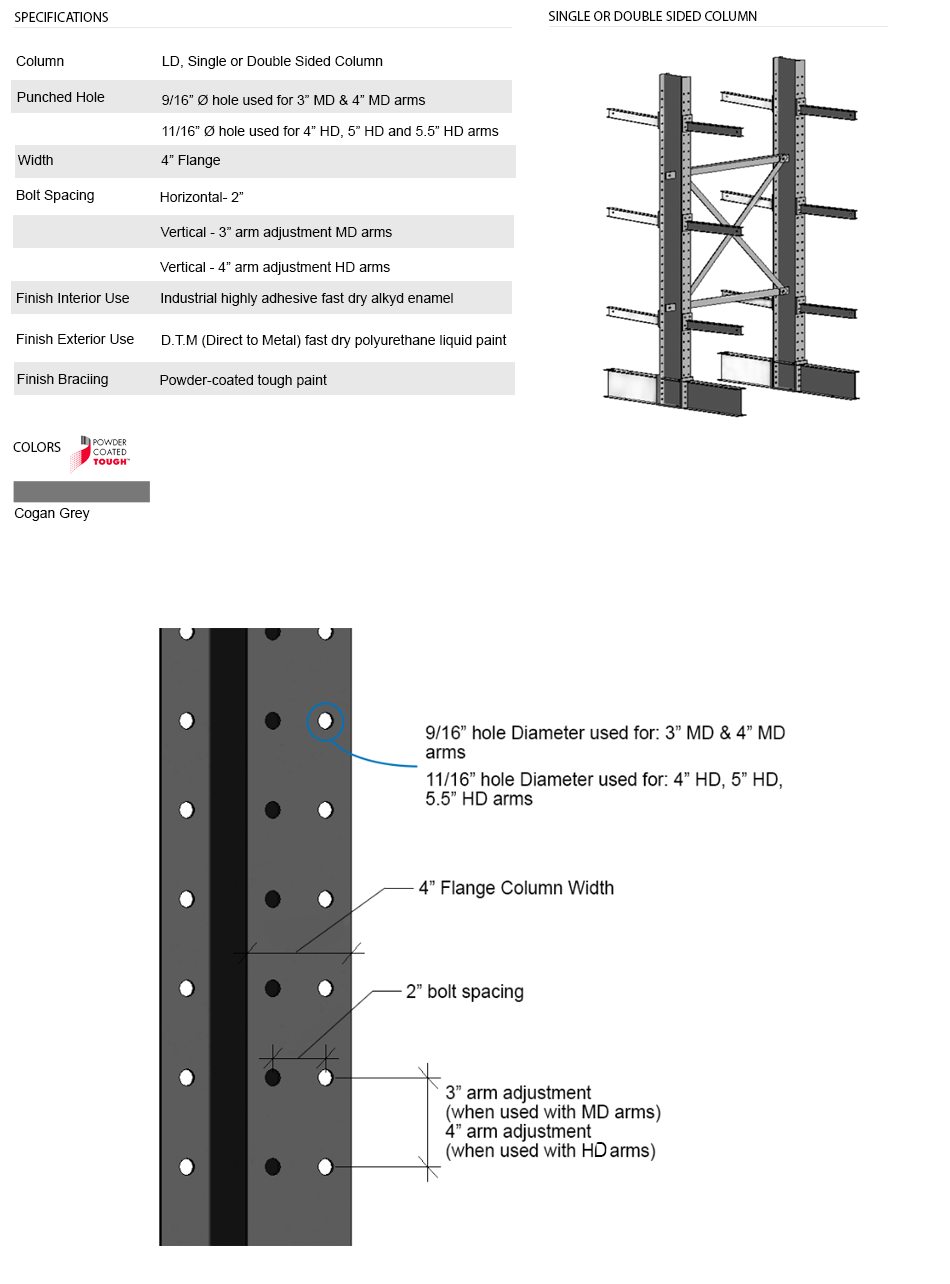

Choose between straight or inclined arms with optional removable arm and base stopper pins. Cogan cantilever racking is available in both single- and double-sided units.

To best suit the needs of your application, Cogan has developed 2 column designs: LD and HD.

- LD Columns use a 4” structural I-beam upright with a 3” vertical arm adjustment. Ideal for medium- to heavy-duty loads.

- HD Columns use a 5” structural I-beam upright with a 4” vertical arm adjustment. Ideal for medium, heavy- and extra heavy-duty loads.

Very Narrow Aisle (VNA) Cantilever Racking

Make the most out of your storage or picking area with Cogan Very Narrow Aisle (VNA) Cantilever Racking. Designed for use with side loader fork trucks, our VNA cantilever racking maximizes storage capacity for a highly efficient use of floor space. The narrow design means our VNA cantilever racking uses as little as half the standard aisle width of standard racking solutions. Your storage capacity doubles and wasted space is eliminated. This is ideal for high-density storage areas or where there is a need for expansion within an existing facility.

Cogan VNA cantilever racking offers the same versatile storage abilities as our conventional cantilever racking, but with added aisle guide rail and end-of-aisle guardrail. These rails work to guide narrow aisle fork trucks through the picking aisles, allowing for faster, easier and more efficient operation. Pick precision is increased and material damage is significantly reduced.

Made of structural angle, choose between two installation options for your guide rail: inserted into the base of each unit or anchored to the floor, independent from the rack structure. An end-of-aisle guardrail is welded on either type of installation to protect the entrance of each aisle and allow forklift drivers to safely navigate around corners.

Both types of guide rail are welded on-site for a maximum fit and precision to create one solid, continuous guide rail.

L or T Shed Cantilever Racking

Create a four-season covered storage unit with Cogan L-shed or T-shed cantilever racking. Ideal for protecting stored materials from harsh weather conditions, the angled roof design allows rain to flow down easily and shields against snow, ice and sun damage. Powder-coated structural steel components and heavy-duty treated wood joists provide superior strength and durability. Lost or damaged material due to severe weather is significantly reduced, saving you costly replacement expenses.

L-Shed or T-Shed cantilever racking is ideal for any outdoor application. Use L-sheds or T-sheds to create efficient storage space in your lumberyard, shipping yard, overflow area, or any situation where outdoor storage is required. Cogan L-shed cantilever racking is single-sided and can be installed against a wall or along the side of a building. Our T-shed cantilever racking features arms on both sides to maximize storage capacity. Your existing cantilever racking can also be retrofitted with an L-shed or a T-shed. This allows you to make the most out of storage systems that are already in place.

In order to account for local weather variances, Cogan L-shed and T-Shed cantilever racking is always custom-manufactured for your exact needs. Important variables such as wind and snow loads, geographical location (country/city/state), and exact physical location of the installation (against a wall or not) are all factored into the engineering process.

Request information about Cantilever Racking

Call here for more information about Unit#: Cantilever Racking

Or fill out the form below