Jib Cranes

Jib Cranes

-1.png?width=100&height=100&name=Untitled%20design%20(3)-1.png)

Downloads

Download the brochureWhat is Jib Crane?

A jib crane is a type of crane that features a horizontal jib or boom, which is an arm that extends horizontally from the crane’s mast or vertical support. This jib supports a moveable hoist fixed to either a trolley or directly on the jib, which can move along the jib’s length. Jib cranes are typically mounted on a wall or floor and can rotate, offering a wide range of motion. The jib’s rotation angle can vary, with some cranes offering up to 360 degrees of movement, making them highly versatile for lifting and moving loads in a circular area around the crane’s base. They are widely used in industrial and manufacturing settings, workshops, and warehouses, particularly in areas that are too small for larger cranes or where quick and frequent lifting is needed. Jib cranes are ideal for localised lifting tasks and can handle loads ranging from very light to several tons, depending on their design and construction.

Floor Mounted Jib Cranes

Floor Mounted Jib Cranes can be used as supplements to a regular traveling crane, monorail track, and more. Browse through the Unified Industries Floor Mounted Jib Cranes for a versatile and cost effective solution.

Unified Floor Mounted Jib Crane

The Unified enclosed track jib crane provides a versatile and cost effective solution to your crane needs where adequate headroom and structural support does not exist. Use as a supplement to a regular traveling crane or monorail track, or for use in bays and along the walls or side of shops.

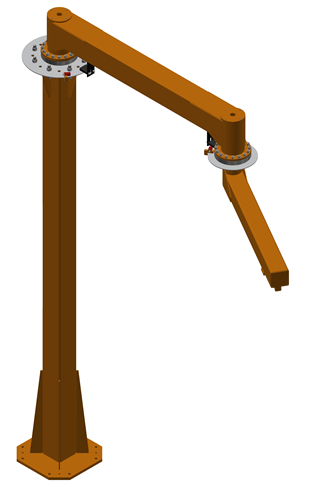

Articulating Jib Cranes

The Unified Articulating Jib Crane design includes an over-under boom design with two 360 degree pivots. This design allows the operator to utilize the complete workspace without losing any ergonomic benefits. Browse Columbus McKinnon’s articulating jib cranes to complete your jib workspace.

Unified Articulating Jib Crane

The Unified Articulating Jib crane is the best choice for applications that require use of the complete jib workspace. As opposed to a standard jib crane where most of the workspace needed is at the end of the boom; the Unified Articulating Jib has an over-under boom design with two 360 degree pivots. This design allows the operator to utilize the complete workspace without losing any ergonomic benefits.

Mini Overhead Cantilever Jibs

Utilize this unique jib in work cells and work areas.

Unique fixed-height design allows for the 39-3/4" long outriggers to be mounted underneath a work bench. Easily lift product from cart to workbench. Straddle width is 47-3/4" (ID). Hoist, trolley and cart not included. Steel construction. Durable blue powder coat finish. Hoists & Trollies sold seperately.

- Works well in cells and work areas

- Design allows to be mounted underneath a work bench

- Easily lift product from cart to workbench

- Steel construction with a painted blue finish

Extra Travel Tri-Post Jibs

Designed for Workstation.

Place over the top of your workbench. Extra travel fixed-height I-beam overhangs workbench to allow lifting of products from cart to bench. I-Beam flange is 2.66" and the height is 4.00". Usable I-beam length is 79-3/4". Hoists & Trollies can be ordered seperately. Steel construction with painted blue finish.

- Tri-Post jib was designed for use in workstations

- Place over the top of your workbench for various applications

- Fixed-height I-beam overhangs allow lifting of products from cart to bench

- Steel construction for heavy-duty strength and durability

Multi-Station Transportable Jib Cranes

True Multi-tasker

Designed for use in multiple locations, includes jib crane and one base socket. Extra base sockets may be purchased for use in other locations. Friction brake design allows positive locking and controlled rotation of heavy loads. 360 degree continuous rotation of heavy loads. Handle most applications up to 1,000 lbs. 6" high I-beam with 4" flange width. Rugged welded steel construction. Requires reinforced concrete pad for installation. Hoists & Trollies can be ordered seperately. Painted finish.

- Unique Jib designed can be used in multiple locations

- Friction brake design allows positive locking and controlled rotation of heavy loads

- Arm manually rotates 360 degrees for maximum versatility

- Rugged welded steel construction provides long lasting use

Portable Jib Cranes

Easy Transport

Unique design allows for easy transportation of jib crane with a fork truck. Empty base models include instructions for proper filling with concrete Base measures 42-3/16" x 42-3/16" x 18"H or 36"H and includes built-in fork tubes. Fork tubes are 7-5/8"W x 2-5/8"H usable on 24" fork centers, for transportation with fork truck. Fixed length I-beam will pivot 360 degrees for complete access. Under I-beam clearance is 10'. Upright vertical column bolts to base. Steel construction with blue painted finish. Units ship knocked down. Not for use as a fork truck attachment. Hoists & Trollies can be ordered seperately.

- Design allows for easy transportation with a fork truck

- Fill standard base with concrete for proper use

- Upright vertical column bolts to base for optimal efficiency

- Steel construction for strength and durability

More Solutions For You

Check out similar products that could be the perfect fit for your unique needs.

Contact Us Today

Have a project in mind? Need a few more details? Fill out the form and we will get back to you as soon as we can.